This laboratory is used for experiments that evaluate comfort, design, and construction of shoes.

Below is a list of the equipment used in this lab.

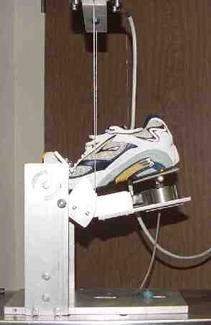

1. Shoe Flex Tester

- Utilizes the MTS Servo-Hydraulic testing machine.

- Evaluates the stiffness, flexibility and responsiveness of the shoe sole and forefoot in flexion.

- Flexes shoes to 55-degree flexion angle.

- Data collected includes: force, moment, stiffness, input energy and output energy.

- This information is used to measure the flexural characteristics of the shoe in relation to the biomechanical response of the foot.

2. ASTM Type A Impact Machine

- Simulates a 150-pound man jogging by dropping an 8.5 kg mass from a height of 50 mm.

- Data collected includes: force, displacement, time-to-peak force, dwell time, stiffness of shoe, acceleration, input energy and output energy.

- Measures the resiliency and shock-dispersing qualities of shoe sole systems.

- This information is used to categorize shoes for shock absorption, stability and general comfort.

3. Artificial Thermal Foot

- Simulates a foot at human body temperature releasing moisture into a shoe or boot.

- Consists of tubing containing water and a heating element enclosed in a Gore-Tex sock, which allows the humidity to travel through but not any liquid water.

- A balance is used to measure the changes in mass that occur when humidity escapes from the inside of the shoe.

- Used to measure breathabilty or the amount of water vapor that is able to escape into the air.